The sensors are already often designed-in and permanently installed into the individual cylinders of a large engine during manufacturing. They provide the combustion pressures and thus the most important information to continually monitor power plants or marine propulsion systems during engine operation. There are different approaches here to increasing efficiency and profitability, while reducing emissions and wear-and-tear:

- Cylinder balancing: combustion variations in different cylinders are compared and tuned to significantly reduce deviations.

- Increase of maximum pressure: conventional, uncontrolled engines are designed so that safe combustion is assured under all operating conditions. Therefore, safety margins regarding the engine’s optimum operating point have to be taken into account.

- Beyond this, cylinder pressure sensors allow large engines to be used with highly fluctuating gas qualities (process gases, bio and landfill gas), which nowadays are difficult or impossible to use and therefore, serve as enabling technology.

Even with a slight improvement in efficiency of say 0.5% to 2.5%, it’s possible to save enormous quantities of fuel. In addition to the huge economic benefits through reduced fuel costs, there is also a significant reduction of CO2 emissions.

Sensor Technology

The special challenge in monitoring and controlling large engines is to ensure excellent data quality over a lifetime of several years under the demanding conditions of a large engine. The sensors are not only exposed to high-pressure surges, but also simultaneously experience tremendous stress due to thermal shock and high acceleration. The piezo-measuring technique is particularly advantageous for these extreme requirements since it essentially measures almost displacement free, in contrast to other sensor technology such as strain gauge (DMS). Thus, the maximum range is within few micrometers or significantly less as a result of the extremely rigid GaPO4 crystals - whereas DMS requires a relatively soft deformation body often requiring 10 times the distance covered during operation. These minimal distortions under such harsh environmental conditions made possible by piezoelectric measurement technology, offer minimal material fatigue and therefore a significant increase in service life and reliability.

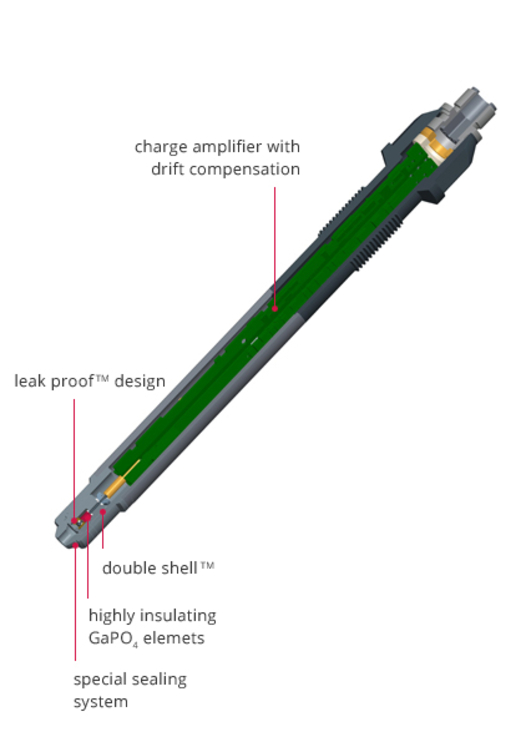

Large engine sensors are equipped with a variety of different technology and sophisticated design details, many of which are patented or patent pending. In addition to the tried and tested Double Shell™ construction, which compensates for disturbances in the cylinder head, or the internal tension element the extremely robust and thermally stable GaPO4sensing elements are used. Alternatives to piezoelectric materials have significantly reduced internal resistance compared to GaPO4. If such crystal elements are used in sensors, many charges are "lost" due to low insulation resistance, and the measuring signals from such sensors are systematically subject to speed-dependent distortion. In contrast, the extremely high insulation resistance of GaPO4 crystal elements is also given at high temperatures, even allowing correct and undistorted reproduction of the pressure signal in low speed 2-stroke engines.

In addition, Piezocryst sensors are equipped with a unique Leak ProofTM safety design. This feature is designed so that even in the unlikely event of a membrane rupture, sensor parts take on the function of a safety valve and seal the cylinder from the environment. Under all circumstances, the leakage of hot combustion gases is prevented, the operator and the engine are protected, and unscheduled engine stops are avoided.

The sensors are equipped with a high quality charge amplifier. This charge amplifier "recognizes" the pressure signal and automatically compensates for any drift. This sophisticated technology makes it possible to avoid the weaknesses of simple charge amplifiers equipped only with feedback resistors and to accurately reproduce signals.