A key factor in increasing quality and efficiency in the area of injection molding is cavity pressure. This value characterizes the filling phase, the compression phase and the holding pressure phase and thus provides the relevant parameters to control and improve the process. For many customers with safety-critical components, quality control and documentation are also of crucial importance to process optimization. For example, product traceability is of central importance in the automotive and medical industry. Through the precise measurement of cavity pressure, all production information for each part is available and can be documented in a component-specific way.

...like our pressure transducer

6011BC

The pressure transducer 6011BC is optimized for reliable measurement of cavity pressure in confined spaces. Because of its special design it is particularly easy to install and has a total length of only 17.2 mm with a detachable cable that can be easily replaced if damaged.

Sensor Technology

In plastic injection molding, temperatures with which melted mass is forced into tools can reach up to 400°C and pressure can exceed 2000 bars. Cavity pressure sensors must be able to withstand these conditions, and very small sensors are required for modern multi-cavity tools. In order to optimally meet various installation situations, the sensors are available in plug-in and screw-type models, as well as different sizes. Regardless of design, all the sensors are equipped with a detachable cable and can be easily used even in the event of cable damage.

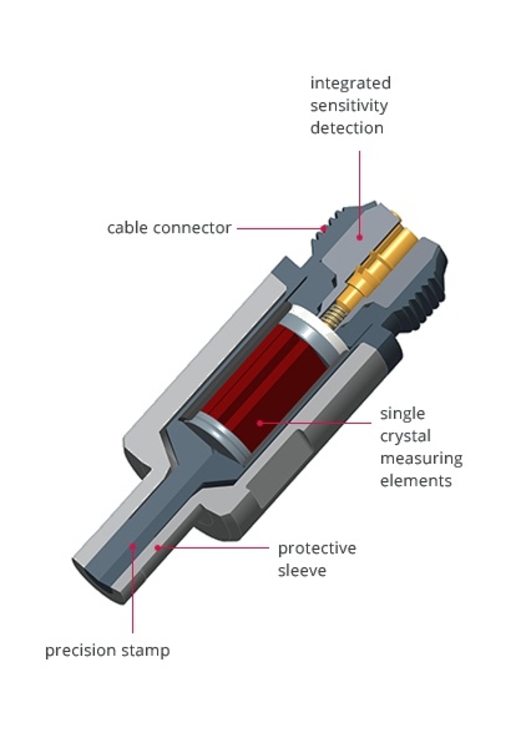

Piezocryst sensors have a precision-machined piston, which transfers the melt pressure onto the crystal elements. This piston is enclosed in a protective sleeve, which largely compensates for bore tolerances in the tool. This technology is also protected by our cooperation partner Priamus System Technologies, as is the automatic sensitivity detection. Here the sensitivity of each sensor is determined and classified by a precision resistor; meaning the sensors have a sensitivity detection that is inextricably connected to the sensor, and in the case of a cable swap, also guarantees the correct read out of individual sensitivity.